Instructions for Using Cooking Oil as Car Fuel: Step By Step Guide

|

| Ways to Make Cooking Oil As Car Fuel: Step By Step - KnowInsiders.com |

| Table Content |

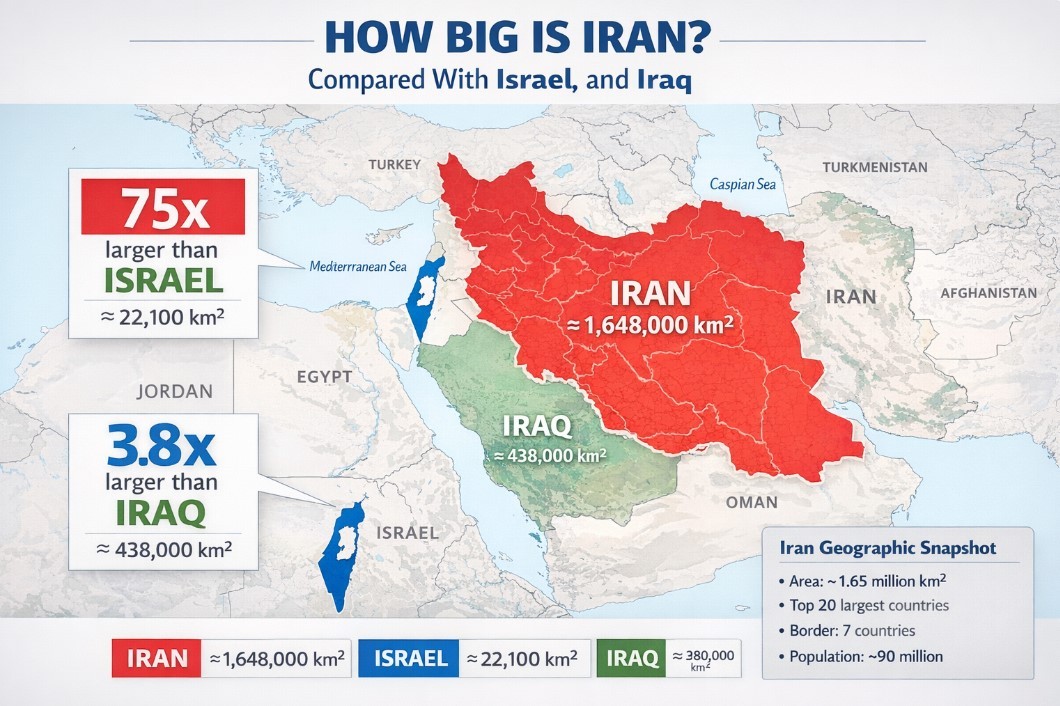

As people become more aware of the negative effects that fossil fuels have on the environment, they are increasingly looking for alternative energy sources that are less harmful to our ecosystems. Solar energy, methanol, and even liquid hydrogen are just a few of the inventive solutions that have been discovered. Vegetable oil, however, is one of the most practical substitutes because it can be converted into fuel strong enough to drive heavy equipment.

There are many electric cars on the road today, some of them can run on solar power, and some even run on liquid hydrogen! But even though these alternatives are getting more affordable, they are still more expensive than diesel or gasoline.

What would therefore be effective? Vegetable oil is one of the most reliable biofuels or alternative fuels! It can power vehicles and even industrial machinery when recycled for use as biodiesel. How can vegetable oil be used as vehicle fuel?

What is biofuel?

According to the US Energy Information Administration, biofuels are substances like ethanol and biodiesel that are naturally produced as fuels.

Ethanol can be obtained from plant starches and sugars like beet sugar.

Animal fats and fresh and used vegetable oils are the sources of biodiesel. It is made by mixing alcohol with vegetable oil, animal fat, or used cooking grease, and it is biodegradable.

To enhance the quality of the oil and maintain its condition during storage, these fuels are typically blended with petroleum fuels (gasoline, distillate/diesel fuel, and heating oil).

Will my car run on cooking oil?

Cooking oil and even used oil that has been strained can be used to power some older diesel engines. On the other hand, the viscosity of cold oil can clog fuel injectors. On the other hand, modern diesel engines need it to be improved, and there are businesses that specialize in turning used cooking oil into biofuel.

How Is Biodiesel Less Harmful Than Diesel?

Used cooking oil can be converted into biodiesel, which is an efficient and secure fuel that won't harm your car's engine. Additionally, it has a number of advantages over conventional petroleum. In addition to being more readily available, it also has a number of advantages over petroleum, such as:

It’s less toxic. As a result, it is both safer to use and safer for the environment and workers.

It’s cleaner-burning. As opposed to conventional diesel, biodiesel burns cleaner. In actuality, pure biodiesel can reduce greenhouse gas emissions and particulate matter by up to 75%.

It needs less transportation. Biodiesel is being produced domestically, so less fuel is consumed – and less gas emitted – by transporting the feedstock or finished fuel.

It reduces waste. Many feedstocks can be used, including used cooking oil from homes, restaurants, and cafeterias.

It’s renewable. Unlike petroleum, which is a fossil fuel and a limited resource, biodiesel can be made from used cooking oil, which is renewable and reliable.

Can to make my own biofuel?

The domestic production of biodiesel is possible thanks to online "recipes." These typically involve combining sodium hydroxide and methanol, then adding the resulting solution to vegetable oil. Due to the use of dangerous chemicals and the possibility of fire and explosion, such home production raises serious health and safety concerns.

Making biodiesel is a potentially dangerous process that needs to be done under controlled circumstances by experts with the necessary education and training. In addition to these dangers, poorly made biodiesel has the potential to seriously harm a car's engine.

How to Turn Waste Oil Into Fuel?

Used cooking oil can be quickly converted into an effective fuel using a certain process. This process, known as transesterification, entails combining the fuel with sodium chloride and alcohol. You will be left with methyl ester, or biodiesel, and an alcohol byproduct after the transesterification.

Sounds easy, doesn't it? It isn't. Do not attempt this at home; leave it to the professionals.

Chemical reactions of any kind can be extremely dangerous if mixed or processed incorrectly because the chemical compounds are tricky to get right.

The Chemistry of Making Biodiesel

|

| Photo: Youtube |

Two chemical processes are required for the production of biodiesel. Typically, the first is referred to as the "methoxide reaction." It occurs when methanol is combined with a catalyst, which may be sodium hydroxide or potassium hydroxide.

Being "exothermic," the methoxide reaction generates heat. Avoid using plastic containers when making methoxide. Plastic has a tendency to dissolve or explode under heat because it can store a static electrical charge. When making biodiesel, stainless steel equipment is always the better choice.

A commercially produced lye is sodium hydroxide; soap-making equipment suppliers sell both potassium and sodium hydroxide online. Get methanol from your neighborhood chemical distributor or a race car shop; race car drivers frequently mix methanol into their fuel. You don't need a license or special authorization to transport 100 gallons of methanol in a pickup truck in North Carolina.

The biodiesel reaction is the second necessary step after the methoxide reaction has gone well. When methoxide and oil are combined and the molecules are stirred, this happens. A mixture of about 80% biodiesel and a 20% cocktail of coproducts will be the end result of the biodiesel reaction. You can either decant the biodiesel from the top of the tank or drain the coproducts from the tank's bottom.

Rules and Regulations for Biodiesel Plants

Make sure to inquire about any potential fuel production restrictions with your local zoning office as well. Keep in mind that in many places, farms are exempt from zoning approval. Inquire about fire-code compliance with the local building inspectors or the local fire marshal as well.

If you want to avoid having totes of glycerin laced with methanol piled up behind the barn, be sure to plan a method for disposing of coproducts when designing your DIY biodiesel plant. The cocktail created by the biodiesel reaction typically contains soaps, free fatty acids, methanol, and glycerin. Some wastewater treatment facilities and some commercial-scale composters will welcome the use of methanol because it is a microbial starter for digesters. Or, you could give it to a helpful local biodiesel producer.

How to Make Biodiesel From Vegetable Oil

Materials for Making Biodiesel

• 1 liter of new vegetable oil (e.g., canola oil, corn oil, soybean oil)

• Sodium hydroxide, also referred to as lye, 3.5 grams (0.12 ounces). Some drain cleaners use sodium hydroxide. The presence of sodium hydroxide in the product—rather than calcium hypochlorite, which is present in many other drain cleaners—should be disclosed on the label.

• 6.8 fluid ounces of methanol (methyl alcohol) in 200 milliliters. Methanol is a good fuel treatment. Make sure the product is labeled as containing methanol (Iso-Heet, for instance, contains isopropyl alcohol and is ineffective).

• Low-speed blender with an option. The blender's pitcher must only be used to make biodiesel. Because the methanol you will use can react with plastic, you should use one made of glass instead of plastic.

• Digital scale to accurately measure 3.5 grams, which equals 0.12 ounces

• 6.8 fluid ounces are marked on a glass container that holds 200 milliliters. If you don't have a beaker, you can measure the amount with a measuring cup, pour it into a glass jar, and then mark the jar's fill line.

• Glass or plastic container that is marked for 1 liter (1.1 quarts)

• Widemouthed glass or plastic container that will hold at least 1.5 liters (2-quart pitcher works well)

• Safety glasses, gloves, and an (optional) apron

Methanol or sodium hydroxide should never be applied to the skin, and neither should their vapors be inhaled. Both are harmful. Please take the time to read the warning labels on the products' containers. Avoid getting methanol on your hands because it can easily be absorbed through your skin. Caustic sodium hydroxide will give you a chemical burn. In a space that is well-ventilated, prepare your biodiesel. If either chemical accidentally gets on your skin, wash it off right away with water.

How to Make Biodiesel: Step by step

• Because a room's temperature below 70 degrees Fahrenheit will prevent the chemical reaction from finishing, you should prepare the biodiesel in one that is at least that warm.

• Label all of your containers, if you haven't done so already, with the phrase "Toxic—Only Use for Making Biodiesel." You don't want anyone to drink your supplies, and you also don't want to serve food in the glasses again.

• 200 ml of methanol (Heet) should be added to the glass blender pitcher.

• On the lowest setting, slowly pour 3.5 grams of sodium hydroxide (lye) into the blender. Sodium methoxide is the product of this reaction, and it needs to be used right away to maintain its effectiveness. It can be stored away from air and moisture, like sodium hydroxide, but that might not be practical for a home setup.

• Add 1 liter of vegetable oil to the mixture after mixing the methanol and sodium hydroxide for about 2 minutes, or until the sodium hydroxide has completely dissolved.

• For 20 to 30 minutes, keep blending this mixture (at low speed).

• Fill a jar with a wide mouth with the mixture. The liquid will start to separate into layers as you watch. Glycerin will be the layer at the bottom. There is biodiesel on top.

• The mixture needs at least a few hours to completely separate. The top layer should be preserved for use as biodiesel fuel. The glycerin is yours to keep and use for other purposes. The biodiesel can be carefully poured off or removed from the glycerin using a pump or baster.

Recycling Your Cooking Oil

|

| Photo: motherearthnews |

One way to benefit the environment is to switch to biodiesel. Recycling used cooking oil is an additional option. Running a commercial kitchen will probably result in a lot of waste oil production. If you arrange for a company, like Cater Oils, to collect your used cooking oil, you can be sure that it will be recycled rather than thrown away.

How to Use Biodiesel

Normally, any unmodified diesel engine can run on pure biodiesel or a blend of biodiesel and petroleum diesel. There are two circumstances in which blending biodiesel with diesel derived from petroleum is absolutely necessary:

You should combine biodiesel with petroleum diesel if you plan to operate the engine at a temperature lower than 55 degrees Fahrenheit (13 degrees C). In cold weather, a 50:50 mixture will function. At 55 degrees Fahrenheit, pure biodiesel will thicken and cloud, which could clog your fuel line and cause your engine to stall. The cloud point of pure petroleum diesel, in contrast, is -10 degrees Fahrenheit (-24 degrees C). You will want to use a higher percentage of petroleum diesel in colder conditions. You shouldn't have any issues using pure biodiesel above 55 degrees Fahrenheit. As soon as the temperature rises above their cloud point, both types of diesel return to normal operation.

If your engine uses natural rubber seals or hoses, you should use B20, a blend of 80% petroleum diesel and 20% biodiesel. Although B20 generally doesn't cause issues, pure biodiesel can degrade natural rubber. If your engine is older and has natural rubber components, you could swap them out for polymer components and run only on biodiesel.

The Key Difference With Vegetable OilVegetable oil (we really mean either vegetable oil or animal fat, but to save us from having to repeat those phrases over and over, we'll just refer to it all as vegetable oil) and conventional diesel fuel differ most in their viscosities when it comes to diesel engines. Compared to diesel fuel, vegetable oil is thicker and has a higher viscosity. Your diesel engine will change as a result of this variation. Vegetable oil will alter how the fuel injectors spray the fuel into the combustion chamber because it is thicker than diesel fuel. Diesel fuel is atomized by fuel injectors in order to burn as efficiently as possible. They aren't made to work with a thicker, more viscous fuel to produce the same result. Therefore, the vegetable oil will be sprayed into the cylinder by the injectors, but the spray won't be as fine. As a result, you'll get a lot more partially or entirely unburned fuel, which will reduce your mileage and increase your emissions. Additionally, all components of the engine involved in combustion, such as the fuel injectors, combustion chamber, etc., will develop significant deposit buildup. Additionally, because it is thicker, you might anticipate that pumping and spraying the thicker fuel will require more effort, which will wear out your injectors and fuel pump. |

How To Clear Cookies On iPhone and iPad How To Clear Cookies On iPhone and iPad When you delete cookies from Safari on your iPhone or iPad, you free up storage space and improve your device's performance speeds. |

Should You Eat Cicadas and How To Cook Cicadas? Should You Eat Cicadas and How To Cook Cicadas? Ignore Cicadas beady little red eyes and set aside their glistening wings and jet-black shell. Just close your eyes and take a bite. Check out ... |

Fact-Check: Use Cooking Oil to Fill Up The Car As Gas Prices Surge Fact-Check: Use Cooking Oil to Fill Up The Car As Gas Prices Surge Can cooking oil be used as fuel for cars - how much does it cost? What if we can use cooking oil to fuel the ... |